Ballistics, science and normativity

Ballistics is the science that studies the behavior of projectiles and the resistance of the materials at impact. The glass formulation requires profound knowledge of the subject for continuous performance improvement.

Optima bullet resistant products are periodically subjected to rigorous tests to comply with international standards and count with certifications by the most prestigious independent laboratories, Beschussamt Munchen, Beschussamt Mellrichstadt, and Chesapeake Testing.

We believe it is important to share some concepts related to ballistic normativity, so we can have a transparent and clear discussion about protection with our clients and the end users:

International Ballistic Normativity Organisations

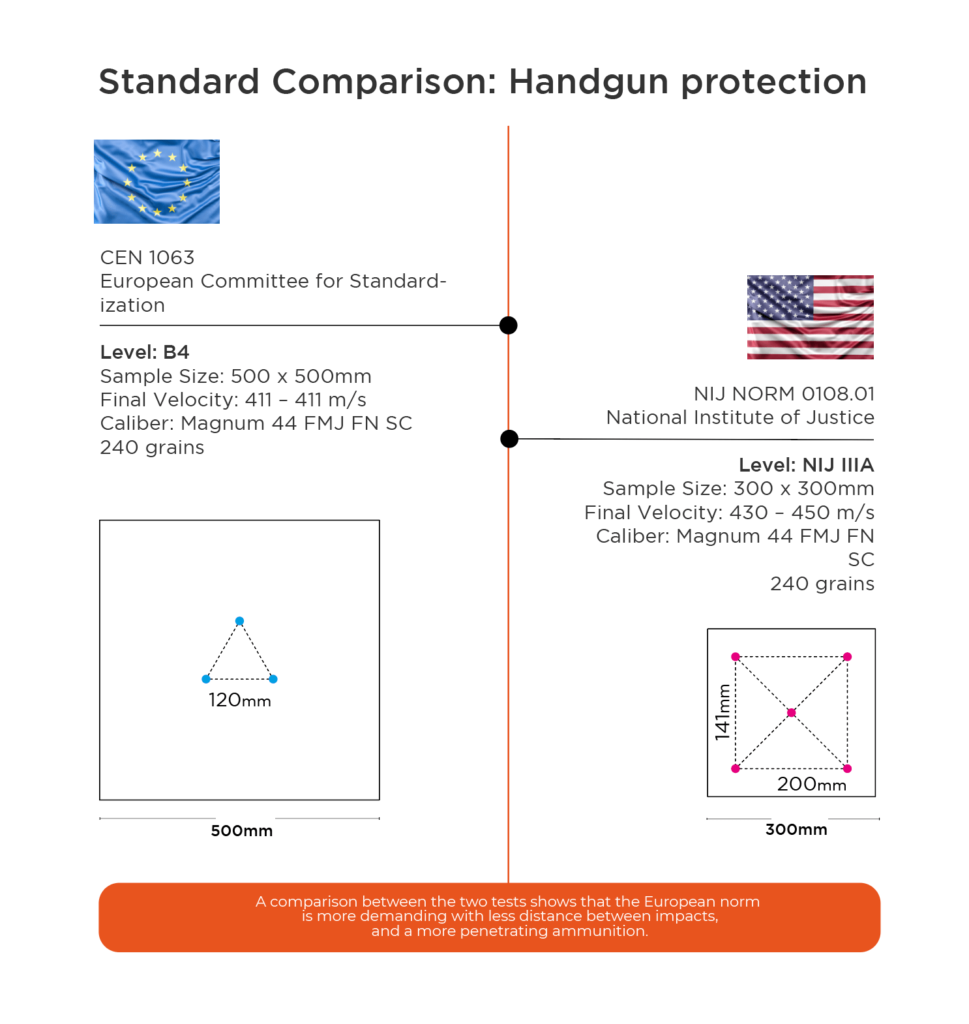

For the European Union the official standards are norms CEN, VPAM or ESTANAC. For the United States, norm NIJ (National Institute of Justice) is the most common, but European Norms are also considered. Used correctly, these standards promote product reliability by providing parameters for a clear conversation about ballistic performance.

Ballistic Normativity

These norms specify the performance requirements and test methods that are useful in classifying the ballistic resistance level of the transparencies.

Ballistic Tests

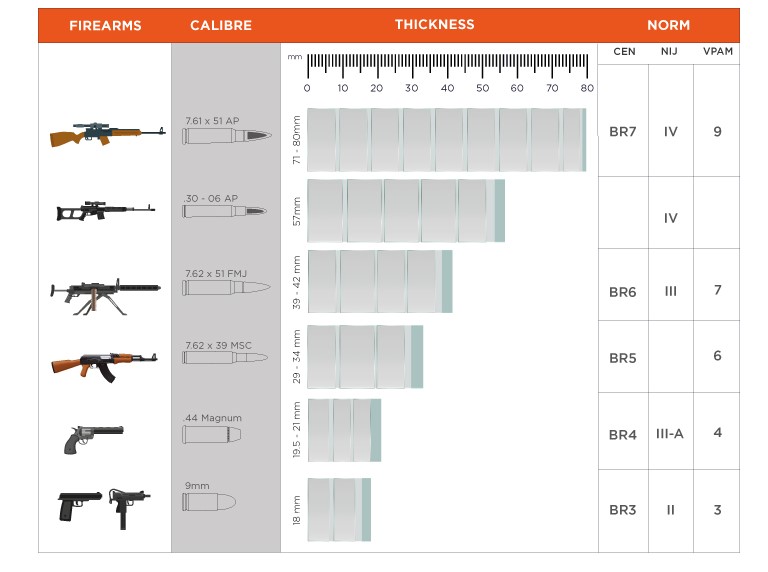

Each ballistic Standard specifies different testing conditions, defining many variables like: Weapon type/ Caliber/ Ammunition/ Weight of ammunition/ Distance to target/ Bullet speed/ Number and position of impacts/ Size of the sample/ and many more.

Ballistics Table

Ballistic certificates

Select the ballistic certificate you want to download.

Select Option

Cert BR5 32 mm

Cert BR6 37.1 mm

Cert EN 1063 BR2 14 mm

Cert EN 1063 BR3 18 mm

Cert EN 1063 BR6 39 mm

Cert EN 1064 BR4 22 mm

Cert EN 1064 BR4 , NIJ III A 19 mm

Cert NIJ III 44 mm

Cert EN 1064 BR7 71.5 mm

Cert NIJ - STD-0108.01 Level IV 55 mm

Cert NIJ III A 18.5 mm

Cert NIJ -STD-0108.01 Level IV 55 mm

Cert NOM UL752 level7 43 mm

Cert NOM-142-SCFI-2000 Level D Class 4 7,62 x 63

Cert Norma V PAM Level 6 PV

Cert Stanag Level I 5.56 x 45 mm

Cert STANAG nivel 1 7,62 X 51 mm

Cert STANAG nivel II 7,62 X 39 BZ API 60 mm

Pruebas especiales 24 mm 7,62 x 39 mm 7 5,56x 45 mm

VPAM Level 6 34 mm

VPAM Level 9 71,5 mm